Working together to find new strategies to eliminate human pathogens in organic wastes through low–energy cost anaerobic digestion.

Waste management is a major global challenge. In Sub-Saharan African countries such as Nigeria and Ghana, inadequate waste management systems pose significant risks both to human health and to the environment. The handling and disposal of human waste- urine and faeces- raise particular concerns, and is one focus of Sustainable Development Goal 6 (SDG6 Water and Sanitation). In 2017, the UN reported that only 45 per cent of the global population had access to safely managed sanitation systems. That’s more than four billion people living without safely managed sanitation. Faecal waste harbours a vast array of microorganisms, some of which can cause serious human diseases. Poor sanitation and hygienic practices relating to the management of faeces and other wastes contribute significantly to outbreaks of infectious diseases in Sub-Saharan Africa.

On the other hand, human waste can be used as a source of energy and fertiliser, for example through the process of anaerobic digestion (AD). Using AD allows “waste” to become a resource to produce biogas, for use as a cooking fuel for example. The material left at the end of AD, known as digestate, can be used as fertilizer to improve crop yields. However, for farmers to use digestate as a fertilizer for food crops they have to be sure that any disease-causing microbes (pathogens) have been destroyed during the digestion process. That poses challenges that can only be solved by research that crosses the boundaries of traditional academic disciplines. Chemical engineers are essential to optimise the production of biogas from AD systems, but are not trained to investigate the use of digestate in crops. That research needs plant scientists, agricultural engineers and soil scientists, but neither they nor the chemical engineers have the expertise in microbiology needed to quantify how AD affects pathogen levels. The only way to make real progress is to work together across all those disciplines. That is exactly what is happening in the GCRF-funded RECIRCULATE project.

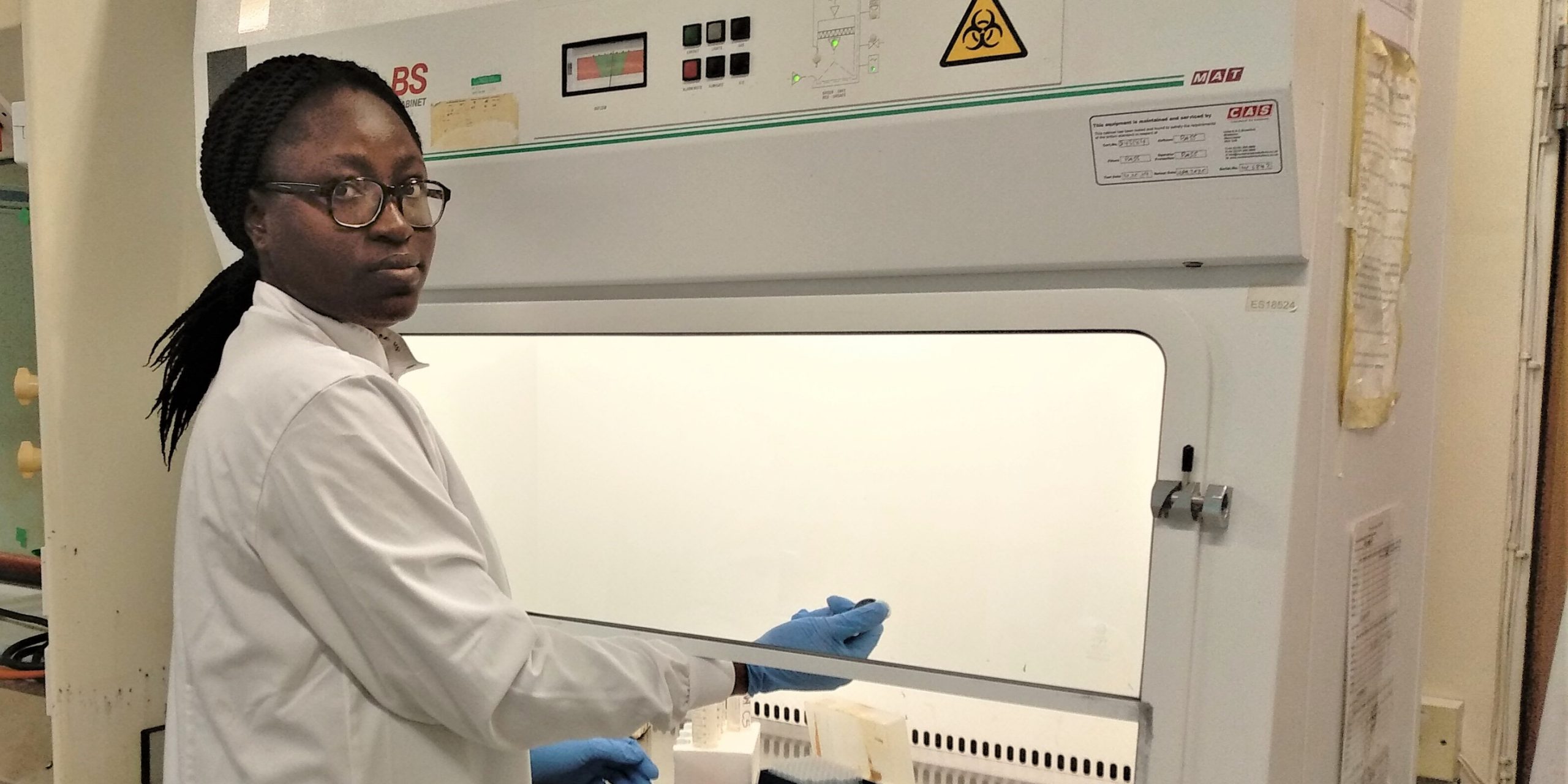

I am part of a cross-disciplinary team of chemical engineers, microbiologists, agricultural engineers, and soil scientists working together to optimise conditions for the elimination of human pathogens in organic wastes during anaerobic digestion. The chemical engineers work to design and develop AD systems that are optimised for biogas production and the elimination of pathogens. The agricultural engineers and soil scientists assess the agronomic value of the pasteurised digestates. I am a microbiologist, so my role is to investigate the decline of pathogens in different AD systems process, and then as digestate is applied to soil. This understanding is essential to ensure that digestate does not contaminate crops with human pathogens.

As a team, we are optimising several factors that influence the destruction of pathogens in wastes during anaerobic digestion. Our aim is to find which combination works best for BOTH biogas production AND pathogen kill. In my microbiological experiments, I started by using non-disease-causing strains of the bacterium Escherichia coli– “E. coli”- as an indicator organism for monitoring what would happen for serious disease-causing microbes, such as Salmonella or Campylobacter. I use strains of E. coli that have been “tagged” to produce red or green light. That makes them easy to identify and count when they grow in Petri dish cultures. More recently I have extended my studies to include several disease-causing bacteria (Klebsiella pneumoniae, Enterococcus faecalis and Clostridium perfringens) that have been reported to survive the AD process in conventional systems. A key outcome of my research will be understanding how their survival is reduced by our innovative AD designs.

I introduce defined concentrations of tagged E. coli and the other bacteria in to laboratory scale AD systems that are set up using different simulated food and agricultural wastes as feedstocks. By taking samples at intervals during the AD process and then growing them in Petri dishes, I can count how the numbers of these bacteria change over time. My results so far have shown that the development of highly acidic conditions during digestion is a major factor in the effective reduction of E. coli populations. With all the microbes that I have studied, I have found that highly acidic AD conditions kill more than 99.999% of the bacteria originally present within 24 hours.

This new information has allowed our chemical engineers to alter the AD set-up to maximise acid production. The improved design will maximise the destruction of pathogens without compromising biogas production.

In the next phases of our research, I will work with the rest of the team to monitor the decline of E. coli in digestate applied to agricultural soil. We will take in to account standard agricultural practices, for example whether or not the crop is watered.

From a personal perspective, it is great to be working with such a diverse team on a project that aims to create a useful fertilizer from what are currently problem wastes. By optimising systems to produce pathogen-free digestate we can encourage improved waste management (SDG 6). Beyond that, we will contribute to the production of clean and renewable energy, and so SDG 7, and improved food production (SDG 2). In turn, both SDG2 and SDG7 make major contributions to SDG 3, which is to “Ensure healthy lives and promote well-being for all at all ages”. Working together, we can help address four of the most important sustainable development goals for sub-Saharan Africa.

|

Saanu Victoria Obatusin is a graduate researcher working at Lancaster University, UK and is completing a PhD funded by Lancaster University contributing to Work Package 4 (Water for Energy Production) of the RECIRCULATE project. Victoria has a Masters degree in Food & Industrial Microbiology and a BSc in Microbiology, both from the University of Benin, Nigeria. Before coming to Lancaster she was a lecturer at University of Benin, Nigeria. |

All articles in The FLOW are published under a Creative Commons — Attribution/No derivatives license, for details please read the RECIRCULATE re-publishing guidelines.